Capsule Fire

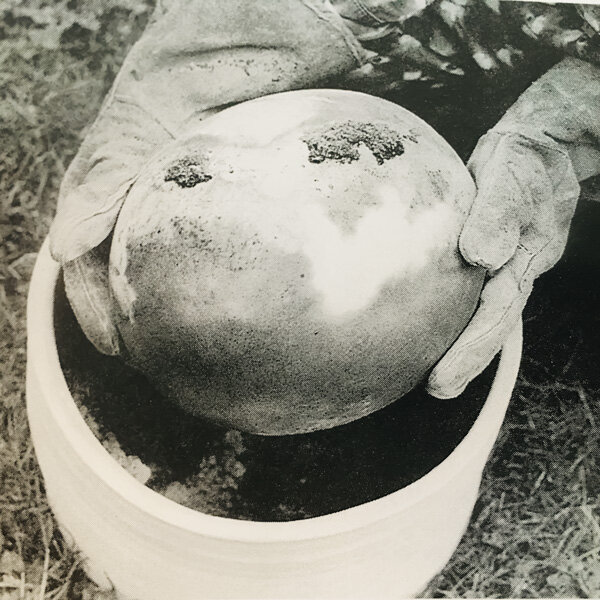

After firing, the object is removed from the capsule.

Open-ended.

It refers to firing in a closed container (capsule) of refractory material in which the ceramics are placed. In industrial production, capsules were previously used to protect the ceramics from direct flame contact and sudden temperature changes.

Today, the capsules are used to achieve special effects on the surfaces of ceramic exhibits and they also enable reduction firing to be carried out in an electric kiln. In this process, the raw or bisque ceramic is fired together with various natural materials and metal salts in a refractory closed container. When the added materials are burned, a reducing atmosphere is created in the capsule, which, in addition to the traces of fume, leaves imprints, colors and patterns on the ceramic that can otherwise only be achieved in gas firing or raku. Firing is usually carried out at a temperature between 1000° and 1150°.